Cass Allen has worked on the acoustic design of many large-scale mixed-use developments containing gyms. The gyms have ranged from small single-room gyms for residents only through to larger independent commercial gyms (Fitness First etc). Here are five key acoustic considerations when designing gyms in mixed-use developments:

1. The location of the gym in the development

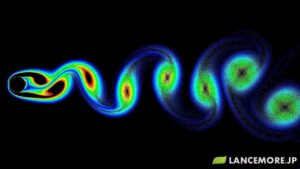

Gyms can generate high levels of airborne and impact noise and so they should ideally be located away from residential units. However, this is not often possible and gyms are increasingly being located in mixed-use developments adjacent to habitable areas. In these cases high acoustic performance separating wall and floor constructions will normally be required to ensure that neighbouring residents are adequately protected.

2. The type and size of gym

Some gyms will generate more noise than others. This depends on the size of the gym but also the type of activities and equipment used in the gym. The following activities/areas generally dictate the type and levels of noise generated:

- Group fitness classes – high music noise levels and potentially high levels of impact noise from people exercising in unison, etc.

- Free-weights areas – high impulsive noise from free-weights impacting on the floor.

- Machine-weights areas – can generate high noise levels from weights impacting on each other and the machine body.

- Cardio-machine areas – bikes, rowing machines etc. These machines tend to be quiet compared with other noise sources.

In medium to large gyms, music tends to be played at high noise levels and often dictates the overall average noise levels with impacts from free-weights dictating maximum impact noise levels.

Cass Allen has carried out a number of noise surveys in gyms of different sizes and types in order to quantify noise levels from different activities and equipment.

3. Appropriate acoustic design targets

To minimise the risk of complaints regarding gym noise, we recommend that new mixed-use developments are designed so that noise from the gym is generally inaudible in adjoining dwellings. This will require a much higher level of sound insulation than the minimum requirements in Part E of the Building Regulations.

Inaudibility is difficult to quantify as it is dependent on the background noise levels at the receptor position, which cannot be accurately predicted if the development is not yet built. In these cases it is necessary to adopt nominal design targets. The following internal noise targets are normally recommended:

- Design targets for maximum gym noise levels in habitable rooms of adjoining residential properties:

- Daytime (0700-2300hrs) – 20 dB LAmax

- Night-time (2300-0700hrs) – 10 dB LAmax

If the development site is particularly quiet it may be necessary to reduce these noise targets.

4. Control of impact sound transmission

Free-weights areas and gym classes can generate high levels of impact noise, which, if unmitigated, is likely to travel effectively through the building structure and disturb adjoining residents. Impact noise from gyms is difficult to quantify and predict and therefore a ‘best practice’ approach is generally proposed whereby the following anti-vibration treatments are included within the gym design:

- Cardio machines, weights machines – Machines placed on resilient floor matting

- Free-weights areas – Resilient floor systems (sprung floor or bespoke resilient floor build-up incorporating mass layer)

- Group gym class areas – Specialist sprung floor systems

Even with the treatments listed above, it may be necessary to impose management restrictions regarding, for example, the hours that the gym can be used, and it is still recommended that gyms are not located directly above residential units wherever possible.

5. Reverberation control

Reverberation treatments should also be considered for medium and large-scale gyms to provide good quality acoustic environments within the gyms themselves. This is particularly important for group class areas where speech intelligibility between the teacher and class members is important. Generally, good internal noise environments can be achieved using acoustic absorptive ceiling or hanging absorbers.

If you would like further information on the acoustic design of gyms in mixed-use developments please call us on 01234 834 862.

We are experienced in the planning, design and testing of large developments for major developers (e.g. Barratt Homes, Berkeley Group, Bouygues, Bellway Homes, Morgan Sindall, Hill Partnerships, Midgard, Kier Group, Mulalley, Mace Group, Taylor Wimpey, Telford Homes, United Living (South) Ltd).