5 steps to avoid complaints about MVHR and MEV noise

Mechanical ventilation noise is a common cause of complaints in new-build residential developments where continuously running MVHR and MEV systems are used (i.e. System 3 or System 4 from Building Regulations Part F). Most new urban developments are ventilated using these systems.

MVHR can be most problematic, as supply air ducts run directly to noise-sensitive rooms (bedrooms and living rooms), however noise from continuously running extract systems in wet room (bathrooms and kitchens) also have the potential to annoy residents, particularly in open plan kitchen/dining/living rooms.

1. Specify noise limits

MVHR and MEV systems should be specified to achieve acceptable noise levels in habitable rooms. Building Regulations Part F states that, to ensure good acoustic conditions, mechanical ventilation noise should not exceed the limits given in table 1 below. These limits should be achieved with the units running at background ventilation rates as a minimum. However, in some cases it may be appropriate to specify systems to achieve the limits in boost mode.

For high value or particularly sensitive properties, it may be appropriate to adopt lower project noise limits.

Table 1 – MVHR/MEV Noise Criteria in Building Regulations Part F

| Room | Noise Limit |

|---|---|

| Bedrooms and living rooms | 30 dB LAeq,T |

| Less sensitive rooms such as kitchens and bathrooms | 35 dB LAeq,T |

2. Careful design

The systems should be carefully designed to ensure that the noise limits are achieved. M&E designers and equipment manufacturers should be asked to confirm that their designs are capable of achieving the noise limits specified as per item 1 above. Cass Allen can review designs where a second opinion is required.

The following noise mitigation measures are recommended as a minimum:

- Inherently quiet MEV/MVHR units should be selected. Units should not be undersized. The specification of cheaper, undersized units is a common cause of unacceptably high MEV/MVHR noise levels. Noise should be one of the main considerations in the selection and sizing of the units. A larger unit run at a lower speed will be significantly quieter than a smaller unit running at a higher speed.

- Fan units should be installed on appropriate anti-vibration mounts and pattresses. There should be no rigid connections between the units and the building structure.

- Duct layouts should be carefully planned with no unnecessary bends in the system. Changes in duct size and shape should be avoided wherever possible.

- Rigid ducting should be used for duct runs (flexible ducting has a much higher resistance to airflow and, where possible, should not be used). Joints between rigid ducting should be mechanically fixed, silicon sealed and/or taped to ensure an airtight seal.

- Where the ducting penetrates walls, the hole in the wall for the ducting should be as small as possible and any gaps between the ducting and the wall should be sealed airtight with a suitable non-setting mastic.

- Diffusers and dampers should be carefully selected to ensure that they will not generate high levels of turbulent noise at the required air flow velocities. Dampers should be located a minimum of 3 (and preferably 5 to 10) duct diameters away from room grilles if possible.

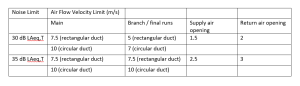

The system should be designed so that the air flow does not exceed the following velocities in ducting, depending on which internal noise limits given in table 1 have been adopted:

Table 2 – Maximum flow velocities in MEV/MVHR systems

Additional mitigation may also be required depending on the design of the system, including:

- In-line attenuators

- Lagging of ductwork above sensitive rooms

- Acoustic enclosures for MEV and MVHR units

3. Installation

Poor installation is a common cause of noise complaints from MEV / MVHR systems. Use of flexible ductwork, unsupported ductwork, unnecessary bends, sharp bends, bodged or poor connections would all result in higher levels of resistance in the system and therefore the MEV/MVHR units would need to be run at higher duties to provide the required air flow rates. This would result in significant increases in noise levels from the MEV/MVHR units and turbulent noise generated by airflow through the system.

We recommend that BPEC approved installers are chosen for installation work to minimise the risk of poor installation.

4. Commissioning

Given how critical installation quality is to the achieved noise levels, the commissioning testing is key to ensuring the system has been installed correctly.

We recommend that independent commissioning is carried out, including noise testing, to ensure that the noise limits are achieved.

Systems should be balanced for the lowest possible fan speed with dampers as open as possible.

As part of the testing, the systems should also be checked to ensure that the MEV/MVHR units are not being run at overly high speeds in order to compensate for poor installation i.e. the required unit duty onsite should be similar to the design duty.

5. Maintenance

Developers should pass on manufacturer recommendations to residents for cleaning and maintaining the MEV/MVHR systems. This is typically a guide outlining a service schedule that the residents can follow to ensure the systems are kept clean and in good working order.

If residents do not maintain the systems, then they will invariably become less efficient and noisier over time.